Product Description

Product Specification:

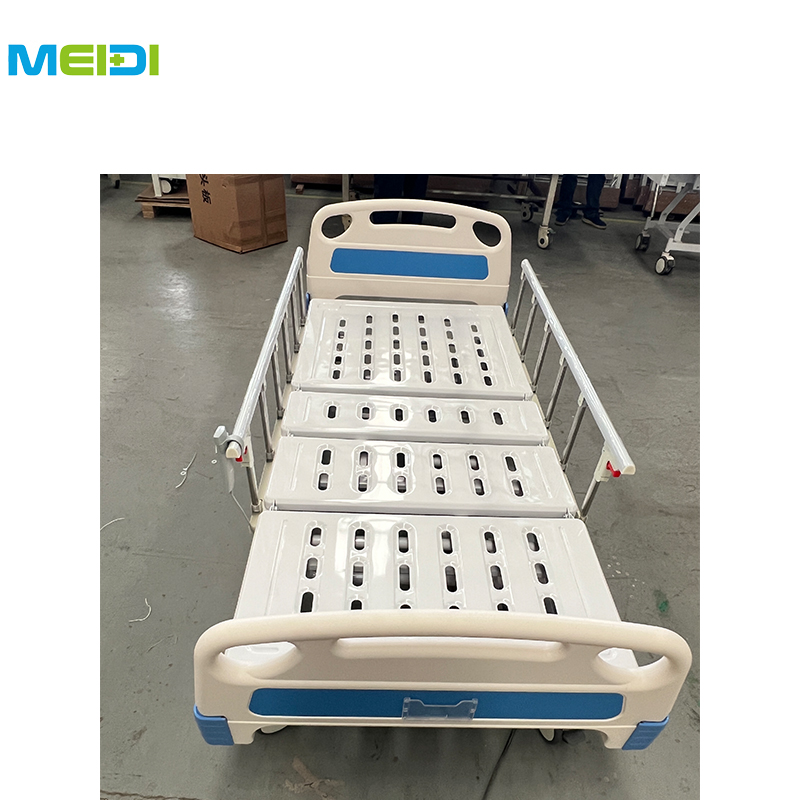

Headboard and footboard:High-strength engineering plastic injection molding for superior strength. The front and back plastics are partially fused together, resulting in a smooth surface for easy cleaning. The hanging design provides excellent stability and easy disassembly.

Bed Panel:Made from high-quality cold-rolled steel sheet ≥1.2mm thick, punched and pressed in a single process. All four corners are seamlessly welded, and the surface is electrostatically sprayed with plastic. Welded reinforcement ribs are located around the back of the bed panel to enhance load-bearing capacity.

Guardrails:Fully covered, six-position folding aluminum alloy guardrails with an electrophoresis-hardened surface. D-shaped ABS handrails with a pinch-proof design retract smoothly and can be raised or lowered as needed. When retracted, the guardrails rest slightly below the mattress, ensuring ergonomic fit.

Handle:Made of high-strength ABS engineering plastic with built-in metal components, a universal joint structure, and concealed, anti-collision feet for durability.

Bed Frame:The bed frame is constructed from 40mm x 80mm x 1.2mm high-quality carbon steel rectangular tubing. The four corners of the bed are injection-molded with ABS engineering plastic for impact protection, ensuring a sleek appearance and preventing falls. IV pole sockets are located at each corner, allowing for flexible placement of IVs.

Casters:The bed legs feature a 50×50×1.2mm steel frame. Four brake casters with a diameter of ≥5 inches are equipped with independent brakes at each corner. They are anti-static, quiet, and provide strong braking performance, ensuring flexible and reliable rotation.

Bed Frame Processing:The entire bed frame is constructed from high-quality cold-rolled profiles, laser-cut and robot-welded, ensuring a sturdy, stable, and smooth bed. Automated spray coating technology then creates a uniform coating with antibacterial, acid- and alkali-resistant,corrosion-resistant, and fade-resistant properties. The bed panels have passed a salt spray test for over 90 hours, remaining crack-free, rust-free, and smooth.

Spraying Process:The entire bed's metal surface is treated using a fully automated spraying line through eleven steps: degreasing and oil removal,

cleaning, pickling and rust removal, cleaning, neutralization, surface treatment, phosphating, cleaning, drying, electrostatic

powder coating, and high-temperature curing. The phosphating process uses a zinc-based material to prevent rust on the inner surface of the material, resulting in a smooth, corrosion-resistant coating with strong adhesion. The surface is powder-coated and has an ivory white finish after high-temperature spraying.